Smart Manufacturing

So, you’re running a production facility, and constantly juggling multiple tasks, trying to keep everything running smoothly. Sounds familiar, right? Well, what if we told you there’s a way to make your life a whole lot easier? Enter smart manufacturing – the superhero of Industry 4.0.

Smart manufacturing brings together the power of Artificial Intelligence (AI), the Internet of Things (IoT), and data analytics to create a seamless and super-smart environment in your factory.

Imagine Jarvis overseeing all your operations, except it’s not science fiction—it’s your business reality, and even more impressive.

With AI algorithms crunching data faster than you can say “optimize,” bid adieu to annoying production hiccups. These algorithms filter through mountains of data generated by sensors and machines to spot patterns and predict potential issues before they even think of causing trouble. It’s like having a crystal ball that tells you exactly when to give your machines a little TLC i.e. prevent breakdowns, extend lifespan, and maintain performance at peak levels, thus saving you time, money, and a whole lot of headaches.

But wait, there’s more!

Smart Manufacturing: Automation is the real game-changer

Picture this: robots zipping around the factory floor, handling routine tasks with the precision of a Swiss watchmaker. Meanwhile, your human workers are free to flex their creative muscles and tackle the real problems. It’s a match made in heaven – humans and robots working together in perfect harmony to boost productivity and eliminate errors.

Let’s come to quality control

With smart manufacturing, you have a team of eagle-eyed inspectors on-duty 24/7. Computer vision and machine learning technologies keep a watchful eye on every product that rolls off the line, identifying defects quickly. Only the finest, top-notch products make it to the market, keeping your customers happy and your reputation bright.

Smart manufacturing and supply chain

But the magic doesn’t stop at the factory gates – it extends all the way down the supply chain. AI-powered systems analyze mountains of data to keep your inventory levels just right, reduce those pesky lead times, and even predict disruptions before they happen. It’s like having a super-smart supply chain guru on your team, always one step ahead of the game.

So, what’s next for smart manufacturing?

Well, the possibilities are endless.

Use case: A leading manufacturer partnered with Cognida.ai to develop a reporting tool that synchronizes data from 19 internal applications and displays insights through a unified dashboard.

These dashboards provide real-time insights, enabling swift decision-making and enhancing organizational visibility. With intuitive interfaces, drag-and-drop feature and other customizable features, the company streamlined operations, optimized resource allocation, and gained a competitive edge in the market.

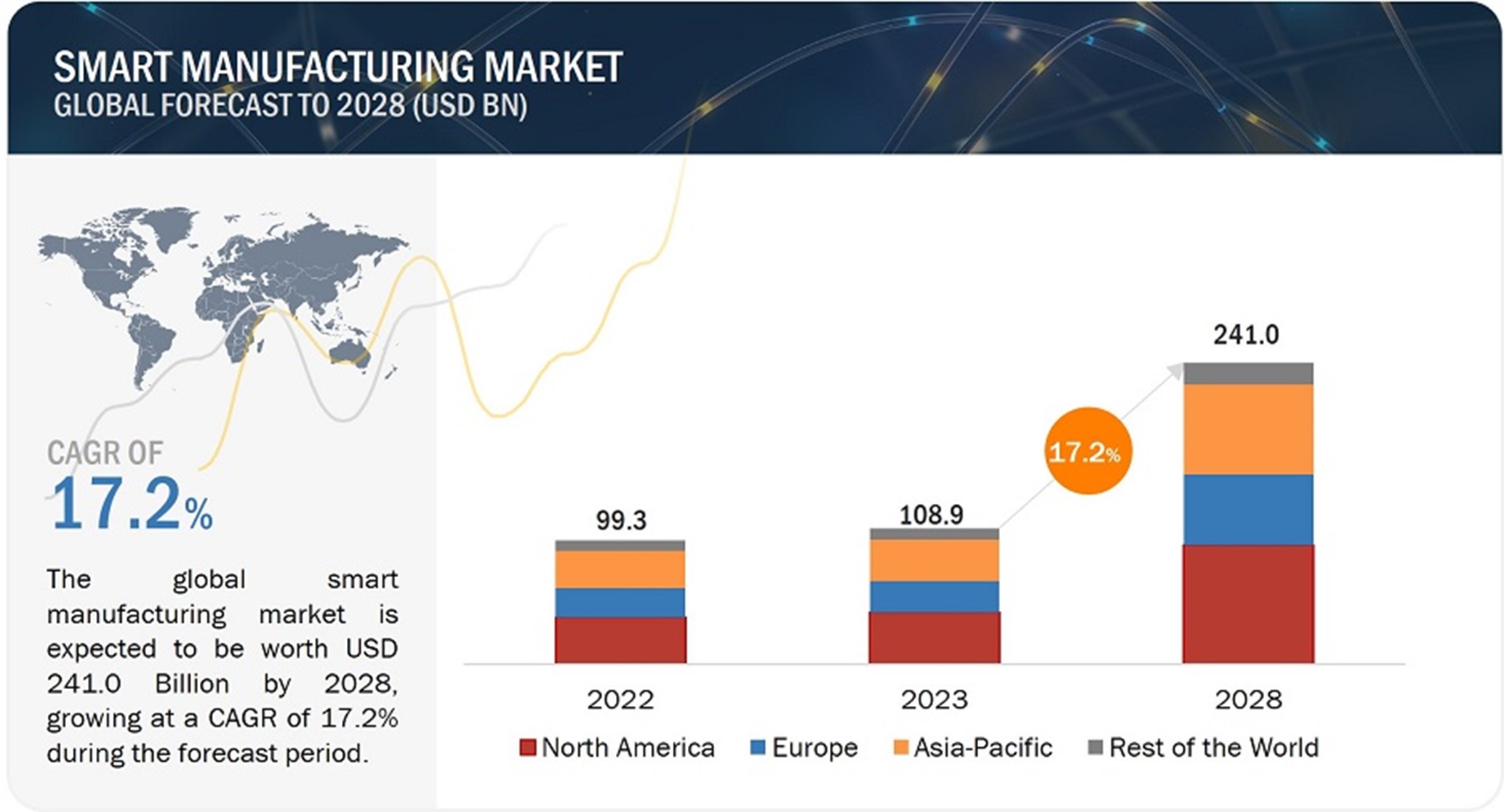

From AI to connected devices and beyond, the future is bright – it will make you super-efficient. With an estimated market size of 241B, it is likely that your competitors are going to adapt to this quickly. Are you going to sit back and watch as the world passes by? Or, are you going to dive headfirst and grab the front-row seat in the world of smart manufacturing?

Embrace the future today and watch your efficiency, quality, and profitability soar to new heights.

Follow us on LinkedIn, if you wish, and let us know your thoughts